Home Hangzhou Qianjiang Chain Industries Co., Ltd. Precision Standard Motorcycle Chains for Motorcycle Parts

Precision Standard Motorcycle Chains for Motorcycle Parts

| Price: | US $ 1.2-1.5/Piece |

|---|---|

| Trade Terms: | FOB,CFR,CIF |

| Min Order: | 1000/Piece |

| Pay Type: | L/C,T/T,Paypal,Western Union |

Specifications

| Prod Model: | 415,415H,420,420H,428,428H,520,520H,525,525H,530.. |

|---|---|

| Markets: | North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Dedicated Chain Type: | Motorcycle Chain |

| Detachable Chain Type: | Agricultural Roller Chains |

| Usage: | Transmission Chain |

| OEM: | Available |

| Chain Size: | 420, 420h, 428, 428h, 520, 520h, 525, 525h, 530.. |

| Series: | Single-Stage |

| Color: | Multi-Colored |

| Trail Order: | Available |

| Samples: | Available |

| Packaging: | Can Be Customized |

| Type: | Chain |

| Material: | Alloy/Carbon Steel |

| Number Of Row: | Double Row/Single Row |

| Surface Treatment: | Polishing/Electroplating/Oxygenation |

Product Description

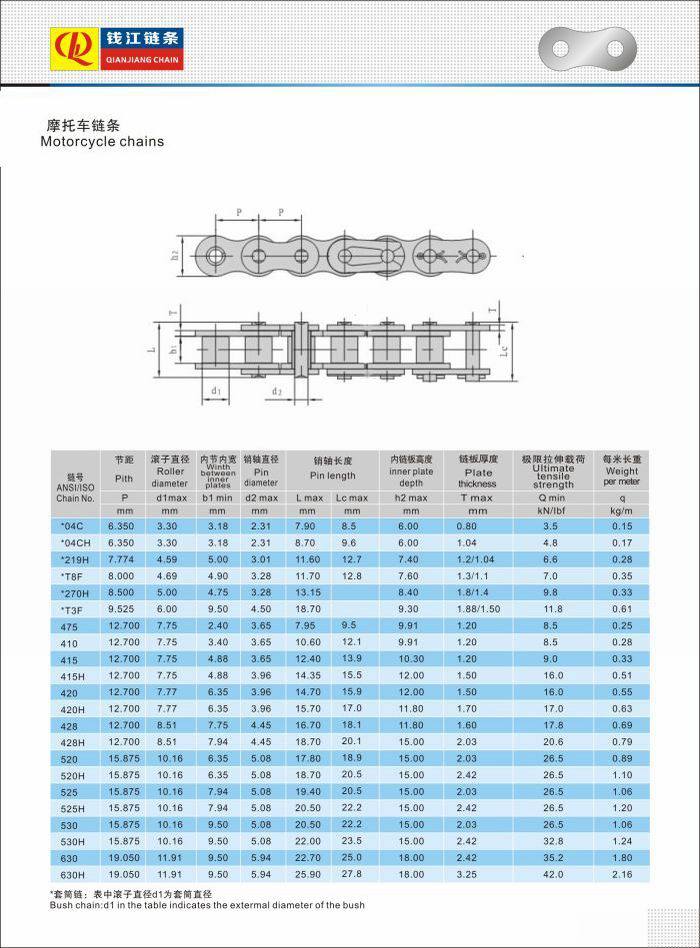

Precision Standard Motorcycle Chains for Motorcycle PartsMotorcycle chains:

1. Materials: Carbon steel, 40Mn

2. Color: Yellow, blue, self, black, colored

3. Model: 25H, CL04, 415H, 420, 420H, 428, 428H, 520, 520H, 525, 525H, 530, 530H, 630, 630H:

4. The chains are fit for Honda Suzuki YAMAHA etc. Motorcycles.

5. All parts are heat treatment (quenching and tempering) and controlled in a reasonable tolerance range.

6. Tensile strength: 15-20% higher than the standard.

7. Certificate of Quality: ISO 9001: 2000, SGS

8. Riveting: Two sides riveting or four sides riveting.

9. Pre-stretching and Running in for each motorcycle chains.

10. Good lubrication with excellent grease.

Products are made of high quality alloy steel production. The plates are punched and squeezed bores by precision technology. The pin, bush, roller are machined by high-efficiency automatic equipment and automatic grinding equipment, then through heat treatment of carburization, carbon and nitrogen protection mesh belt furnace, surface blasting process etc. Assembled precision by Internal hole position, spin riveted by pressure to ensure the performance of the entire chain.

Specifications

| Technique Treatment | |||

| 1 | Shot Peening | 8 | Tempering |

| 2 | Bluing | 9 | Oiling |

| 3 | Nickel-plated | 10 | Greasing |

| 4 | Zincing | 11 | Special color |

| 5 | Heat Treatment | 12 | Stain proofing |

| 6 | Carburizing | 13 | Pre-stretched and anti-fatigue |

| 7 | Quenching | ||

1. Any of your kind inquiry conveyor chain would be replied within 24 hours.

2. Well-trained and experienced sales staffs will reply all your concerns in fluent English.

3. OEM services are available with us, our professional designer would make your private idea into being.

4. Protection of your sales area, ideas of design and all your private information.

5. Delivery by air mail or ship for your orders.

Why choose us

1. We are the manufacture.

2. We have near 30 years experience of making chains and chain links.

3. Our design team has extensive experience in the chain design.

4. Best service and prompt delivery.

5. We offer various styles, size and colors to meet your requirement.

6. We covering a production area of 18750 square meters have more than 200 employees and we have a complete set of testing equipment to ensure our quality.

More >